How to Replace Rotors & Pads on 2016 Chevy Malibu Limited LTZ

What You'll Need

- Torx Bits for Rotor Security Screw

- 1/4 and 3/8 in Ratchets / Socket (17mm)

- Wrenches (11/16 and 14mm)

- Brake Cleaner

- Caliper Rewind Kit (size 6 bit)

- Wrenches (11/16 and 14mm)

- Difficulty: 3/5 (Moderate)

- Time to Complete: 2 to 4 hours

- Cost: Up to $160

Products Used

The Problem

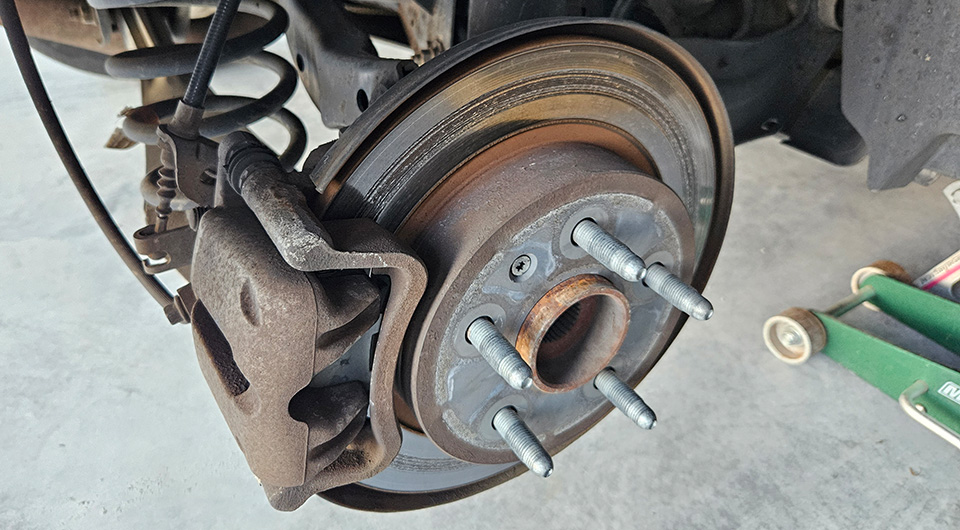

Customer is feeling very noticable wobble at higher speeds, especially when applying brakes. Upon inspection, we see the rotor has extreme wear. Considering how long the customer has been driving with these rotors, we'll replace both, and the pads.

The Solution

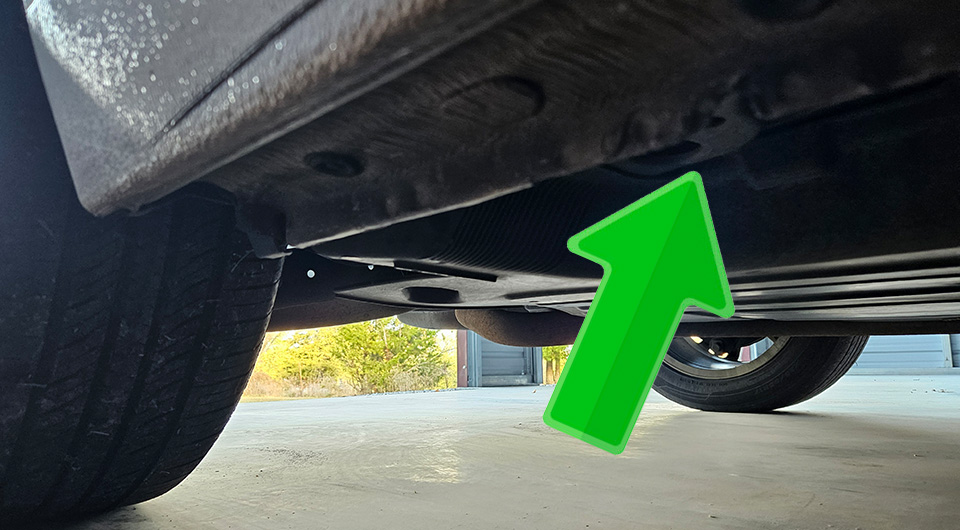

Start by loosening the lug nuts with the vehicle on the ground, then using the jack point beneath the rear doors to lift the vehicle. Then finish removing the wheel.

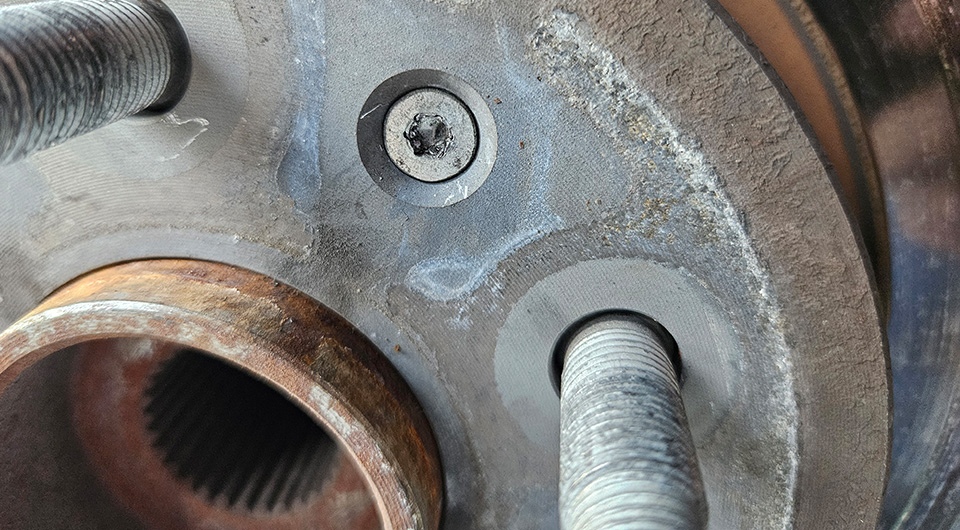

The first order of business is removing this security screw. Use the appropriate-sized torx bit on a ratchet to undo it. The rotor will move while you do so, so stick a board or long object between the wheel hub bolts and vehicle body to hold it in place. Or just use them muscles.

A trained eye may notice that the screw shown here is already stripped. I was unable to remove it using the above method, and actually had to drill it out. See How in "How to Replace Rotors Like a Pro"

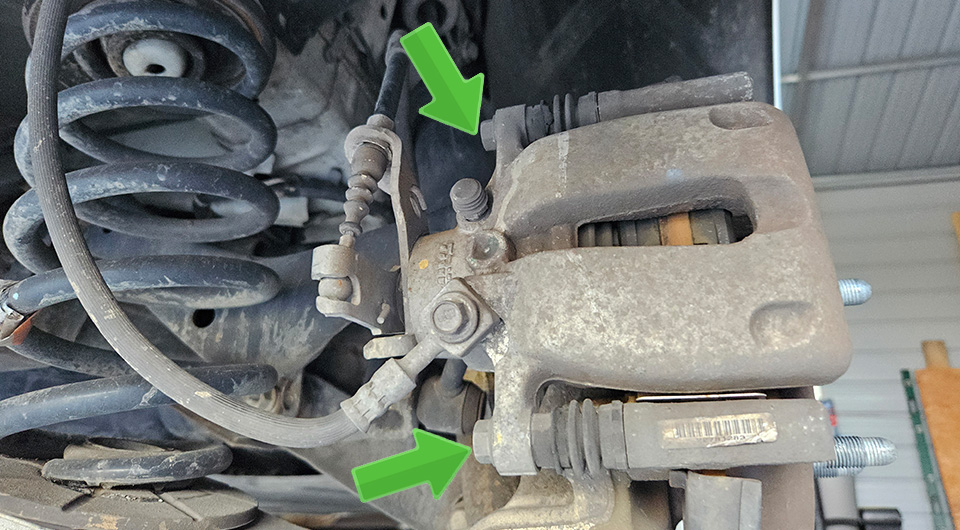

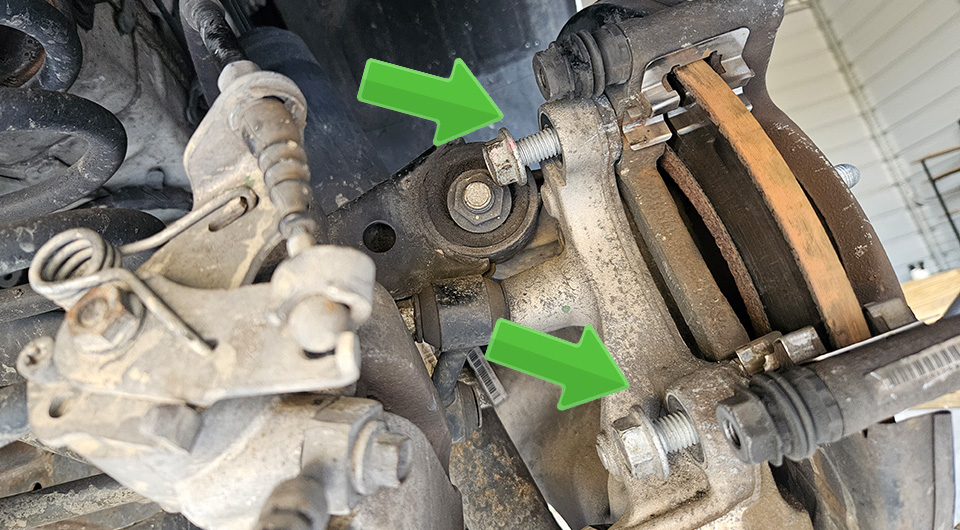

Next, we'll remove the caliper bolts. You don't have much room for a socket and ratchet on this one, so I recommend using the hand wrenches listed above. The caliper bolt itself is 14mm. You may need a breaker bar if the bolts are torqued hard. Be cautious not to turn the bolts the wrong way and break them off in the slide pins.

If the outside caliper slide bolt moves with the caliper bolt such that you can't undo it, use an 11/16 wrench to hold it in place like so.

Remove the existing brake pads from the caliper assembly. Then, it's time to remove the caliper assembly bolts, which are usually torqued pretty hard. You may need a breaker bar for additonal leverage on these. You also once again don't have a lot of room, so if you're having trouble getting a socket on them, just manuever as much of it as you can on the bolt, and very carefully remove the bolts so you don't round the bolt heads.

If you've survived this far, you're in the home stretch! Remove the caliper assembly and existing rotor. Time to put the new rotors on. Be sure you spray your new rotors with brake clean, as there's always gunk on them from manufacturing.

At this point, installation is simply the reverse of removal with ONE caveat. You'll likely need a caliper rewind tool to move the brake caliper back in, such that the caliper will slide down over your new brake pads. You can rent this tool free at most auto parts stores. I used size 6 in this case.

I'll post a guide soon on how to use these kits, but for now, use the Youtube. Rewind your brake caliper back in. Put your new rotor on, install the security screw (if using), re-install the caliper assembly, the brake pads, and caliper. Make sure the caliper assembly bolts are quite tight as they need fairly heavy torquing. The caliper bolts themselves just need to be tight.

Then just put the wheel back on and mostly tighten the lug nuts in a star pattern. Drop the vehicle, and tighten extra-tight. You don't want your wheel coming off down the road, but you also don't want it to be impossible to remove the wheel again after a year. Thanks for reading!

Conclusion

After new rotors and pads on both sides, this customer's car began driving like new again. She noted greatly improved braking power, and much better handling with no further wobble at high speeds. Another happy customer!